Letterbox lettering is much more than a functional necessity. It is a statement that conveys the aesthetics and identity of the house to the outside world. In modern mailbox manufacturing, the focus is primarily on two technologies: laser engraving and laser cutting. But which method is more suitable for inscribing your mailbox? In the following article, we highlight the features and advantages of both technologies to help you decide.

Laser engraving: precise and aesthetic

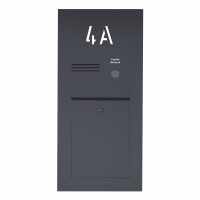

Laser engraving is a method in which the surface of the material is given a new structure by heating. For stainless steel in particular, this results in an attractive, dark gray or light-colored inscription. For powder-coated surfaces, the techniques "foaming up" or "burning away" are used. With "burn away", the underlying, usually ground stainless steel becomes visible. The "foaming" method is used for surfaces without a stainless steel substrate and creates a contrast that depends on the color.

Laser engraving allows for easy cleaning and maintenance, making it a popular choice for name and house number lettering on mailboxes. Its precision and the ability to use a wide variety of fonts and logos without restrictions make it particularly attractive.

Lasercut: Clear contours and lighting options

With lasercut, the lettering is cut out of the material, either as an aperture to be placed on top or as a direct laser cut with a background. This method is particularly indispensable for illuminated house numbers and names, as the Plexiglas on the back contains the lighting element.

However, laser cutting also has its disadvantages. The method requires that bars remain standing to prevent letters or numbers from falling apart. This leads to limitations in the choice of fonts and the design of logos. In addition, laser cutting tends to collect dust in the joints, making it difficult to maintain.

Conclusion: the choice is yours

Both laser engraving and laser cutting have their merits. While laser engraving allows for precise and low-maintenance lettering, laser cutting offers clear contours and the ability to create illuminated lettering. The decision ultimately depends on your aesthetic preferences and the specific requirements of your mailbox lettering. At Briefkasten Manufaktur, we make it a point to offer you both technically flawless and design-perfect solutions to meet your individual needs.

COLOR SELECTION

COLOR SELECTION