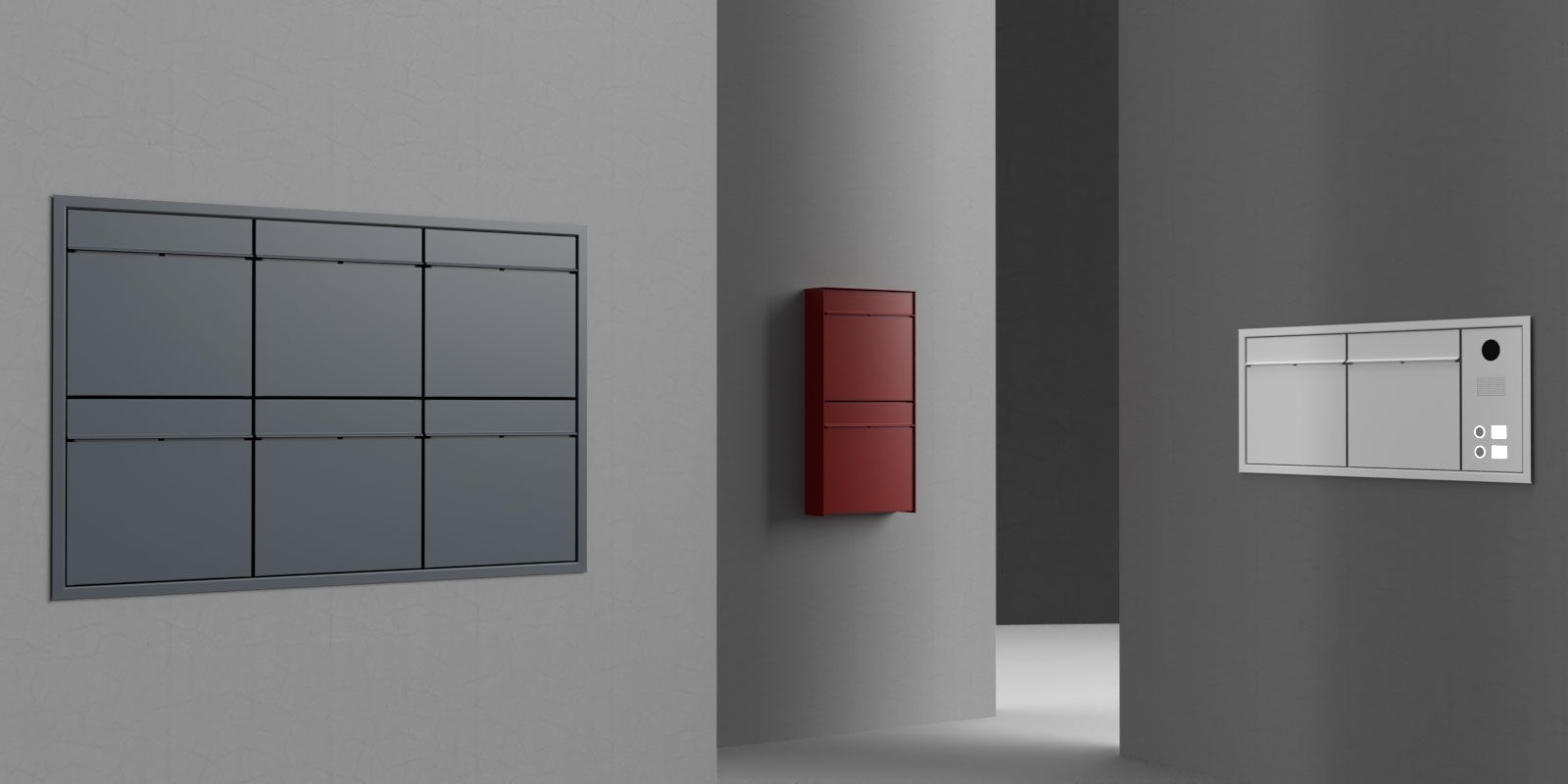

Power & socket pillars - flexible power supply for outdoor areas

Socket pillars are a proven solution for providing power where fixed building connections are missing or impractical. Whether in the garden, on the patio, on campsites, in residential complexes or in commercial outdoor areas - a socket pillar enables safe and convenient access to electrical power directly at the place of use. Devices such as garden tools, lighting, pond technology, e-mobility or temporary consumers can be reliably connected without long cable runs or temporary solutions. The fixed stand installation creates a tidy, permanent infrastructure for outdoor areas.

Advantages of socket pillars in daily use

Compared to conventional outdoor sockets, pillar sockets offer significantly greater flexibility and clarity. Several sockets can be grouped together in a central location, making them safer and more efficient to use. High-quality materials such as galvanised steel or aluminium as well as weatherproof constructions with a rain cover provide protection against moisture, dirt and mechanical stress. This makes socket pillars particularly suitable for permanently installed outdoor applications where reliability, safety and durability are paramount.

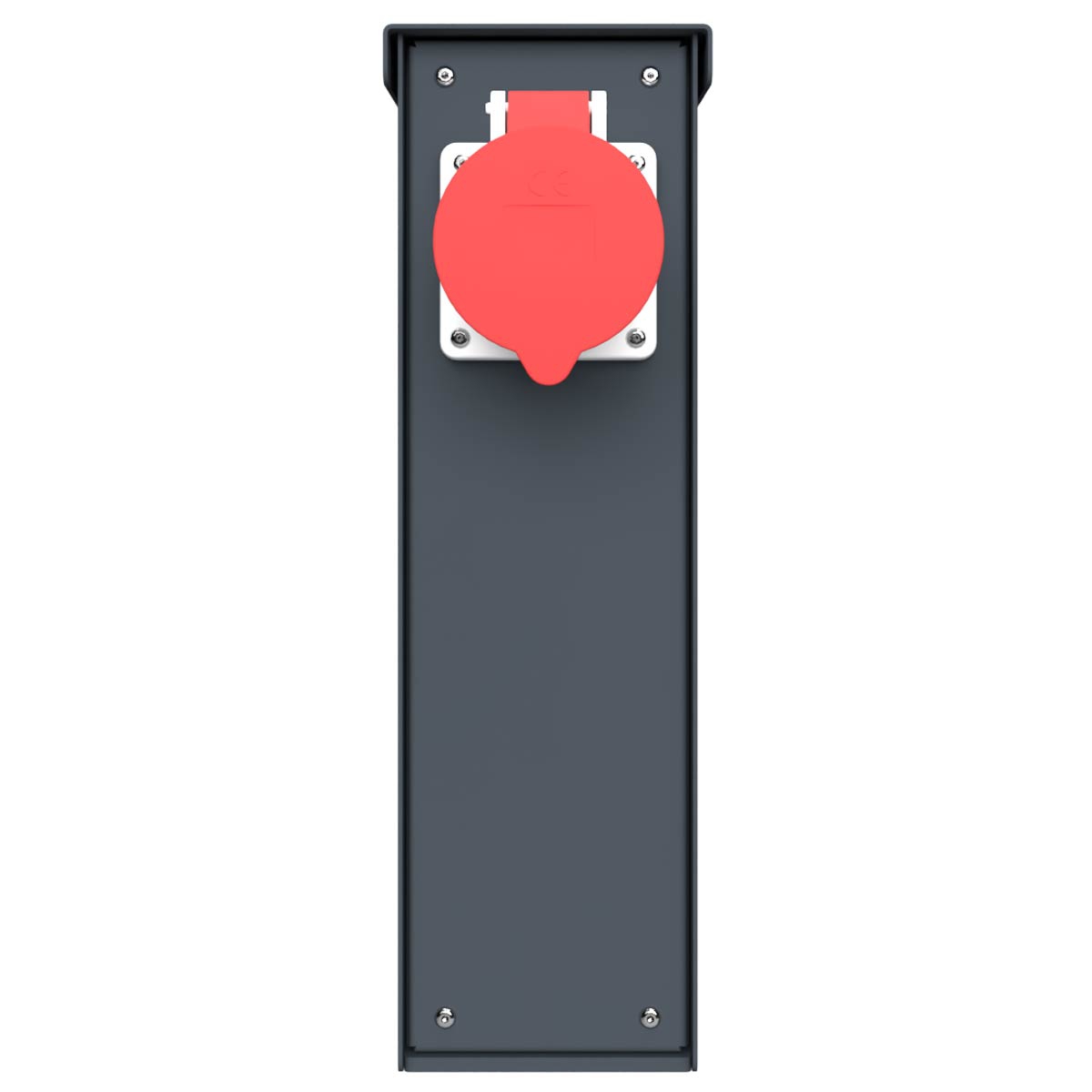

Quality, ease of installation and versatile areas of application

In this category you will find high-quality power and socket columns made in Germany. Sophisticated designs enable simple installation: the column is fixed to the floor, electrically wired and then closed.

Protected socket outlet modules and neat cable routing contribute to operational safety. Whether for private outdoor facilities, professional camping infrastructure or commercial power distribution - modular socket pillars combine functionality, durability and a functional design for a reliable power supply in outdoor areas.

Modular socket pillars - customisable and future-proof

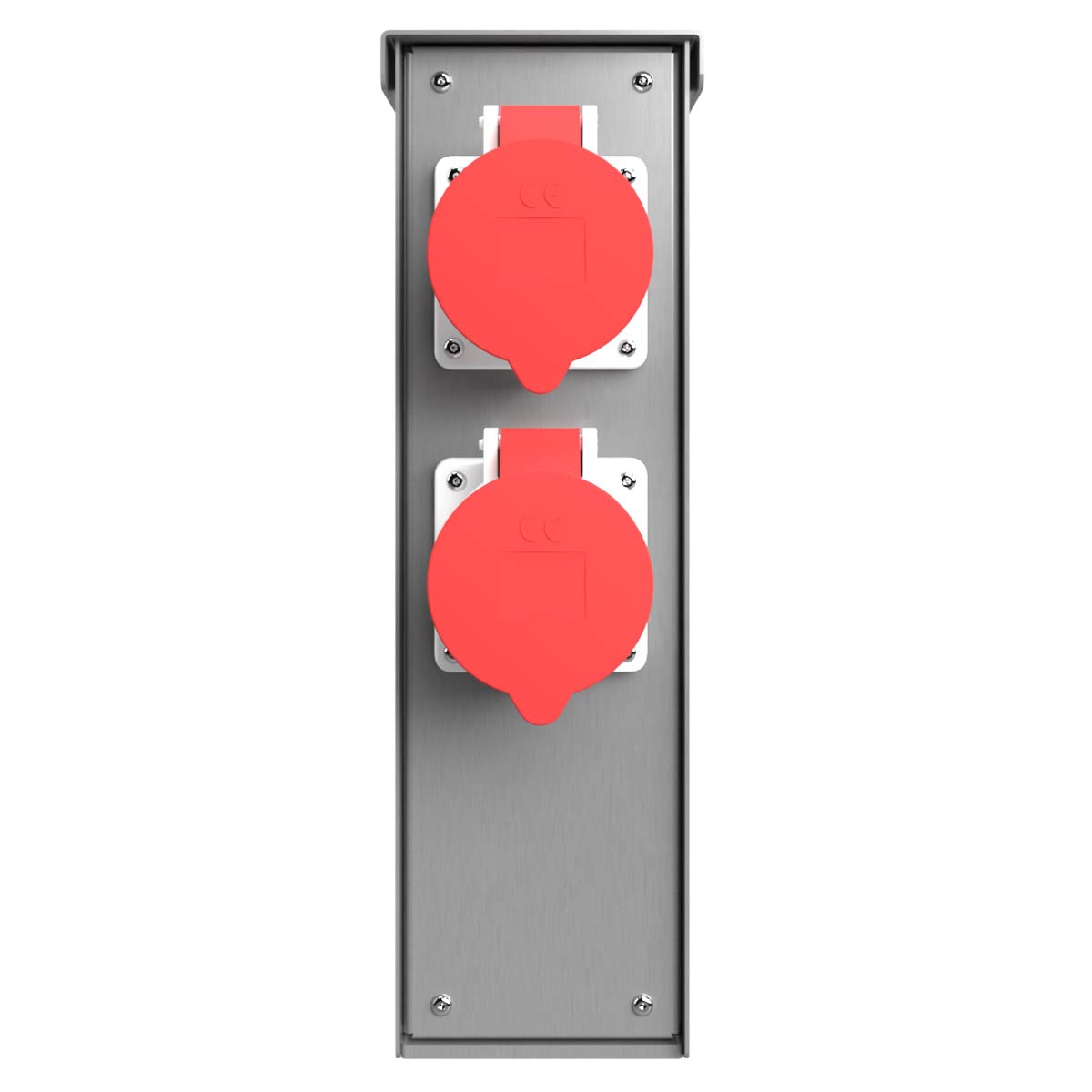

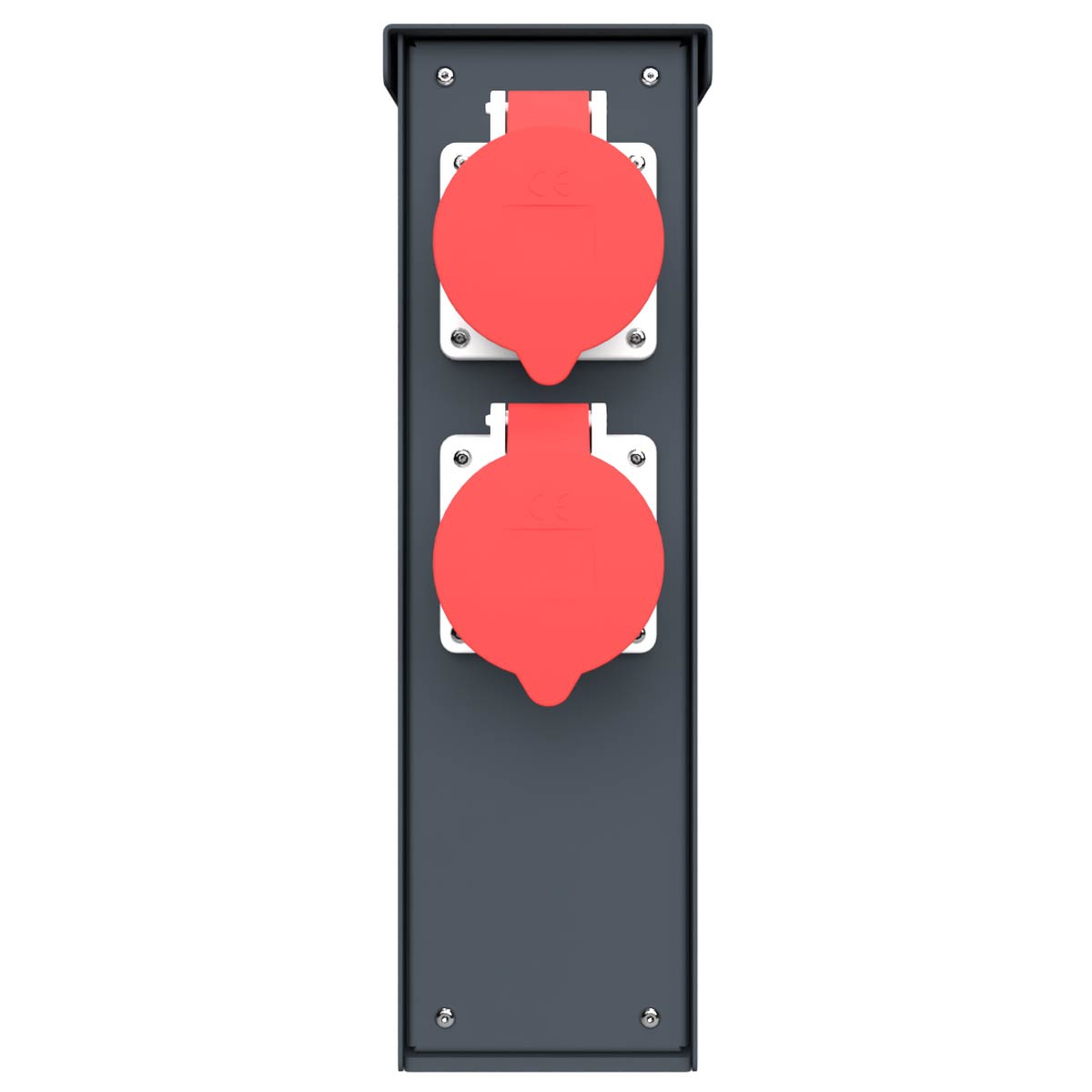

A particular advantage of the modern BML energy management solutions are modular socket outlet columns. Thanks to the modular design, the equipment can be individually adapted - for example with safety sockets (Schuko), CEE sockets, switches, LED lighting, water connections or prepared modules for your own switch and control programmes. Depending on requirements, different types of socket outlets can be combined or easily replaced and extended at a later date. This makes modular socket pillars particularly future-proof, as they can be adapted to changing usage requirements without having to replace the entire pillar.

Outdoor socket pillars - technology, safety and materials explained clearly

For outdoor sockets, an RCD (≤ 30 mA) is generally required according to current VDE requirements and is implemented as standard in practice. The RCD protects against dangerous fault currents and significantly increases safety.

The RCD can be located in the house distribution board or implemented upstream as a protection module. The design and testing should be carried out by a qualified electrician.

Surge protection is particularly recommended when sensitive consumers are operated outdoors, such as control systems, power supplies, pond or irrigation technology. Surge protection is often implemented centrally in the distribution board or via upstream protective devices instead of being integrated directly into the socket column.

An outdoor socket column should meet technical and design requirements:

- Weather-resistant, low-corrosion materials

- Suitable IP protection class (at least IP44, IP55 often recommended)

- Professional connection to the mains supply

- Residual current device (RCD) and suitable fuse protection

- Stable, secure installation (e.g. foundation or ground anchor)

Important: Installation in outdoor areas should always be planned and carried out by a qualified electrician.

Many socket columns are designed for 230 V / 16 A. This corresponds to a maximum power of approx. 3,680 W per socket (under ideal conditions). However, the decisive factor is the total load of all connected consumers and the design of the supply line.

Protection is usually provided by a circuit breaker in the distribution board. For multiple sockets or higher continuous loads, expert planning is recommended (wire cross-section, protection, selectivity).

UV resistance is important because sunlight causes long-term wear and tear on materials and coatings. High-quality socket columns rely on UV-stable surfaces (e.g. suitable powder coating) and weather-resistant components. For visible plastic parts, explicit attention should be paid to UV stability in order to prevent embrittlement and fading.

In principle, you can install a power strip column in your garden yourself. This includes earthworks, laying the foundations and erecting the column. However, for safety and liability reasons, the electrical connection to the mains must only be carried out by a qualified electrician.

According to VDE guidelines, connection to the 230 V mains supply is reserved exclusively for qualified electricians. Carrying out electrical work yourself can be life-threatening and will result in the loss of your warranty and insurance cover. Only preparatory work such as laying foundations, installing empty conduits and erecting the column is permitted.

- Only carry out installation when the power is off

- Use suitable protection class and seals

- Use RCD ≤ 30 mA

- Only use cables for outdoor use (e.g. NYY-J)

- Comply with VDE and manufacturer specifications