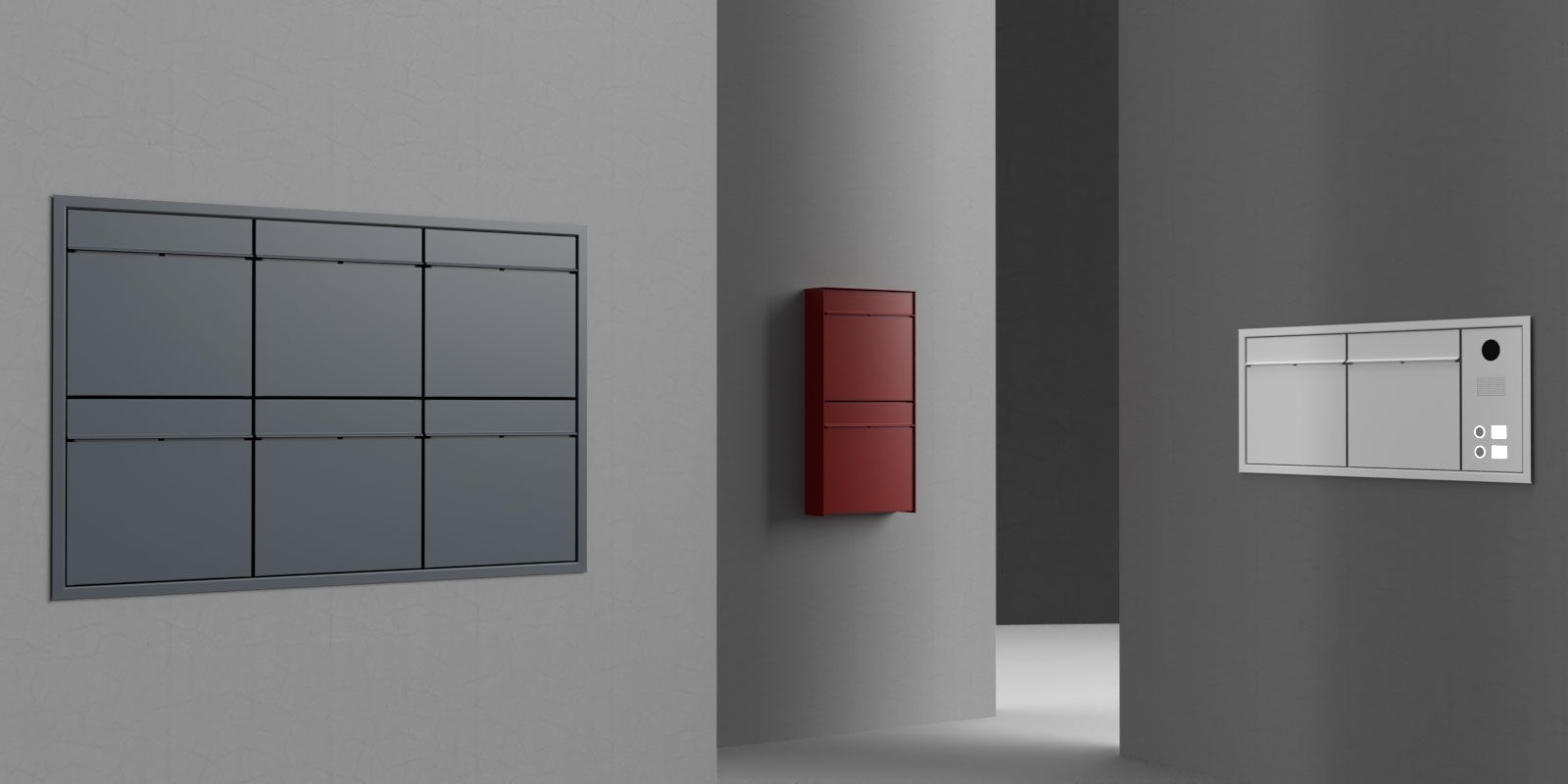

Vous avez choisi un produit de qualité

La manufacture de boîtes aux lettres ne sélectionne et ne travaille que des matériaux de qualité supérieure, garants de longévité et d'élégance intemporelle.

N'oubliez cependant pas que les matériaux nobles doivent être entretenus. Des influences environnementales normales peuvent déjà provoquer des salissures, voire des modifications de la surface. En particulier dans les agglomérations industrielles ou à proximité de la mer, des dépôts sous forme de rouille volante peuvent se former et attaquer le matériau. Dans ce cas, les installations devraient être nettoyées et entretenues plus souvent.

Nos conseils d'entretien

Veuillez noter que : Les produits de nettoyage ne doivent pas contenir d'acide chlorhydrique, de chlorures ou d'hydrocarbures. Il ne faut en aucun cas utiliser de la laine d'acier, des brosses en acier ou des produits similaires lors du nettoyage de l'acier inoxydable, car de tels outils endommagent la surface protectrice et permettent la formation de rouille erratique par abrasion. Les phénomènes de corrosion causés par la rouille volante sont exclus de la garantie.

Nous utilisons entre autres de l'acier inoxydable pour nos produits. Utilisé et entretenu conformément à sa destination, cet acier se caractérise par sa résistance à l'eau, à la vapeur d'eau, à l'humidité de l'air, aux acides alimentaires et aux acides organiques et inorganiques faibles. Après le montage de la boîte aux lettres, un premier nettoyage doit être effectué afin d'éliminer les éventuelles salissures dues au stockage, au transport ou aux résidus de construction ou de montage. Les couches protectrices en papier, les films ou les résidus d'adhésifs doivent être entièrement éliminés après le montage, car ils peuvent entraîner de la corrosion. La boîte aux lettres doit ensuite être entretenue toutes les 3 à 4 semaines environ. Nous recommandons à cet effet notre spray d'entretien pour acier inoxydable. Remarque : les produits nettoyants ne doivent pas contenir d'acide chlorhydrique, de chlorures ou d'hydrocarbures. N'utilisez en aucun cas de la laine d'acier, des brosses en acier ou des outils similaires pour nettoyer l'acier inoxydable, car ceux-ci endommagent la surface protectrice et favorisent la formation de rouille due à l'abrasion. Les traces de corrosion causées par la rouille superficielle sont exclues de la garantie. Les surfaces en acier inoxydable doivent toujours être nettoyées dans le sens du brossage.

Les produits de nettoyage oxydants ou mécaniques ne doivent pas être utilisés, car ils attaquent la couche anodisée. Attention ! Protégez les pièces en aluminium du ciment, de la chaux, du plâtre, etc..

Nous recommandons un nettoyage hebdomadaire et un traitement au moins quatre fois par an avec de la cire pour voiture pour les surfaces peintes ! Pour le nettoyage, utilisez uniquement de l'eau claire avec quelques gouttes de liquide vaisselle et une éponge douce. Les surfaces peintes doivent en outre être séchées et vitrifiées avec un polish pour voiture. Attention : n'utilisez pas de produits nettoyants contenant du vinaigre.

Pour nettoyer la surface du revêtement en poudre, vous pouvez utiliser de l'eau et une petite quantité de nettoyant doux. Si cela est absolument nécessaire, vous pouvez également utiliser une petite quantité de white spirit. Rincez ensuite à l'eau et avec un nettoyant doux !

Le verre acrylique (plexiglas) ne doit pas entrer en contact avec des solvants organiques tels que des diluants, des alcools, des carburants, etc. Les nettoyants pour vitres contiennent généralement de l'alcool. Pour le nettoyage, utilisez uniquement de l'eau claire avec quelques gouttes de liquide vaisselle et une éponge douce. La poussière ne doit jamais être essuyée à sec.