€799.00*

previously €799.00*Delivery time approx. 30 - 34 business days

Can't find anything suitable? Configure your letterbox individually!

Flush-mounted letter box CLASSIC 534C - Titanium brass similar to gold - 1 party

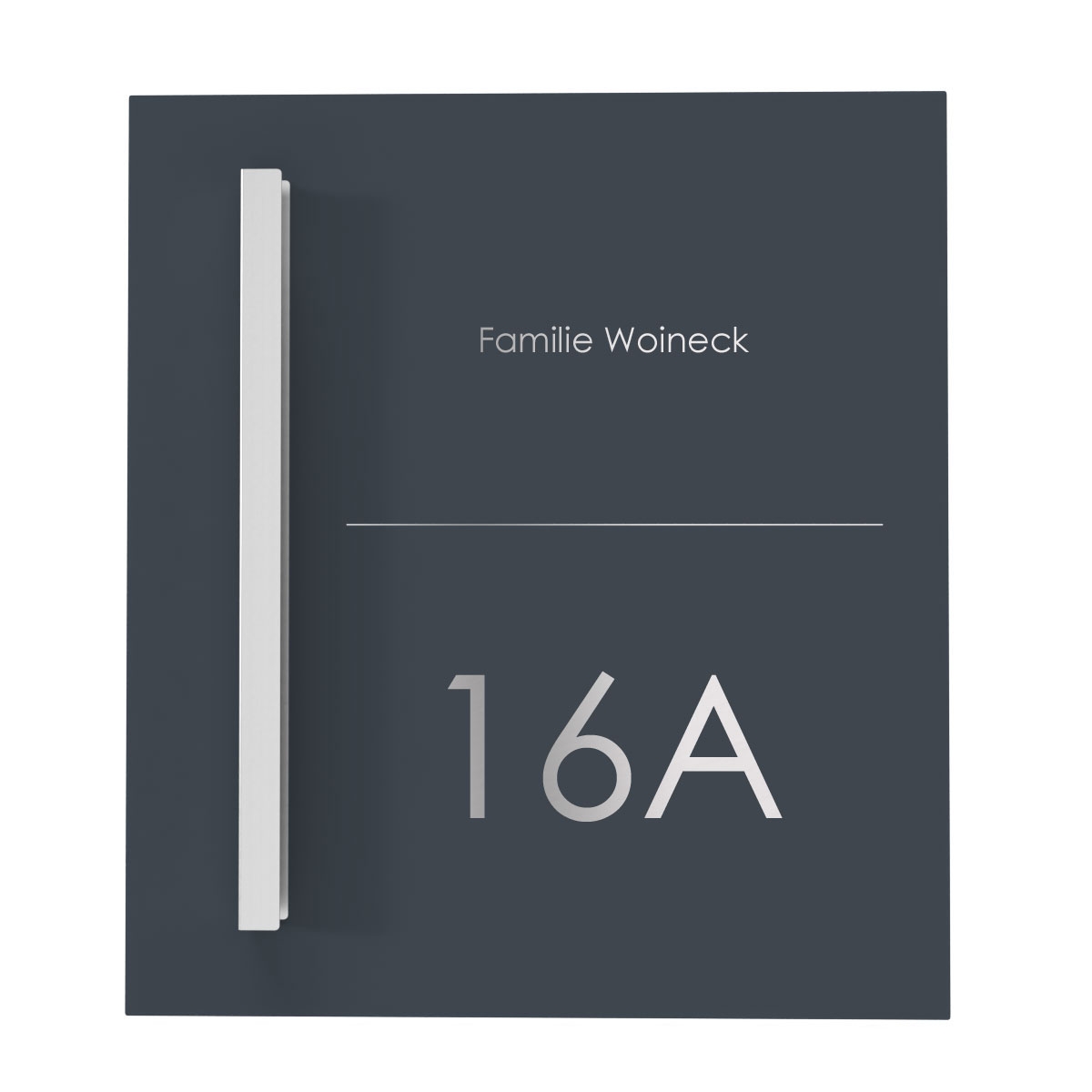

This elegant flush-mounted letterbox has a titanium brass surface similar to gold. The dimensions are ideal for daily mail volumes. A rain drainage edge for optimum water protection, a damped throw-in flap, the solid interchangeable nameplate, a practical post holder and the very robust lock ensure convenience.

- Flush-mounted letterbox with polished stainless steel PVD "titanium brass" front.

- Inner housing made of galvanised steel, grey powder-coated.

- German quality production "Made in Germany".

- Plaster cover frame 20 mm all round made of polished stainless steel PVD "Titanium brass".

- The letterbox complies with DIN/EN 13724. Insertion size (3.3 cm x 33.6 cm) for C4 landscape, large letters also fit in here without creasing.

- Insertion flap with flap damper for very quiet mail insertion.

- The removal door can be opened from left to right.

- Incl. 2 keys with key number, interchangeable name plate under the flap and post holder.

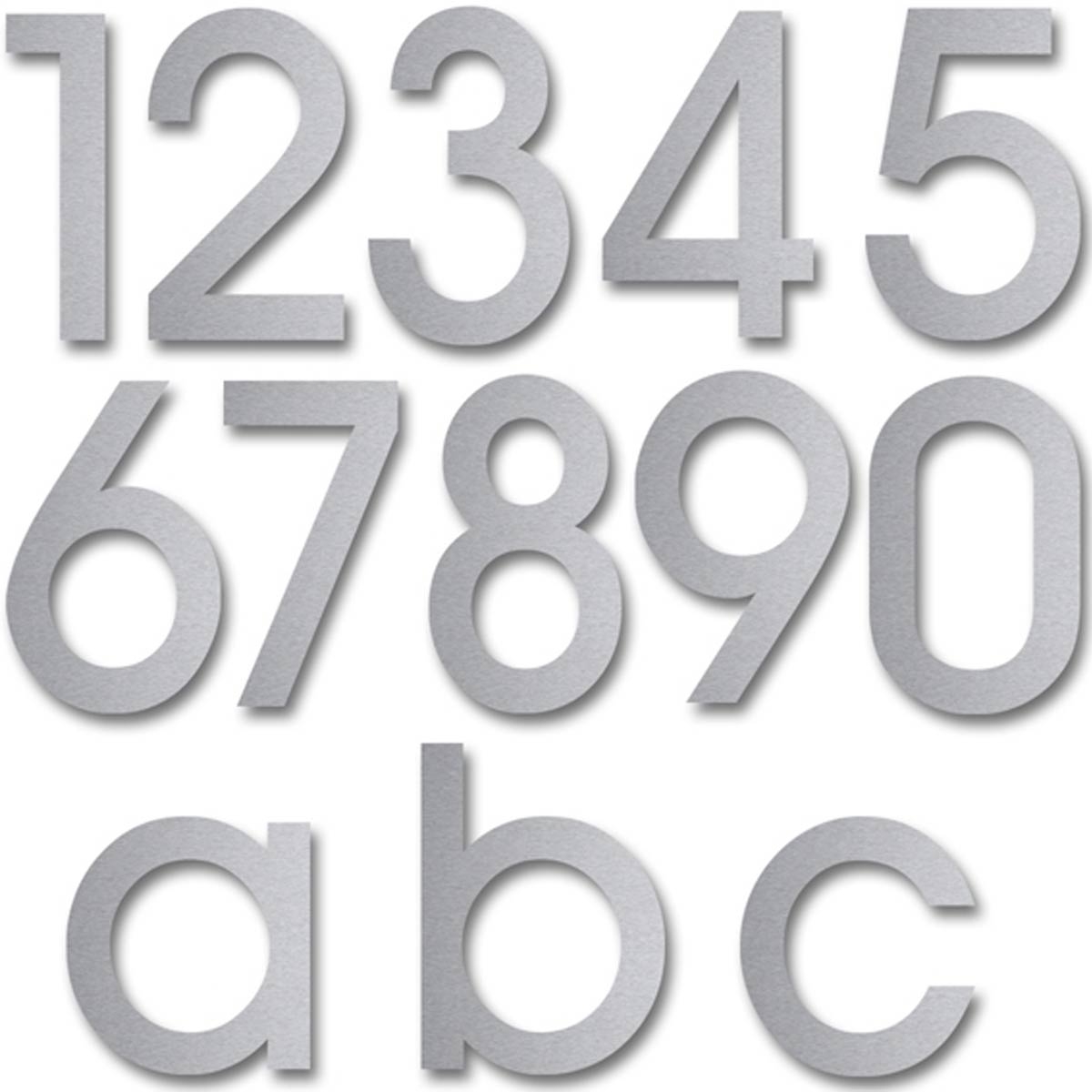

- The labelling on the name plates can be changed as required.

- The post holder prevents the post from falling out when the door is open.

- Installation dimensions or cut-out dimensions: W 370 mm x H 330 mm plus 15 mm all round.

- For flush mounting with surface-mounted plaster frame.

| Material: | Stainless steel V2A 1.4301, Steel, galvanised |

|---|---|

| Number of boxes: | with 1 letterbox |

| Removal of mail: | On the front |

Briefkasten Manufaktur Lippe GmbH

Werler Str. 60

32105 Bad Salzuflen

Deutschland

info@briefkasten-manufaktur.de

| Height of single box in mm: | 330,0 |

|---|---|

| Width of single box in mm: | 370,0 |

| Capacity in litres: | 12 |

| Height of letterbox slot in mm: | 33,0 |

| Width of letter slot in mm: | 336,0 |

| Height of letterbox in mm: | 370,0 |

| Width of letterbox system in mm: | 410,0 |

| Depth in mm: | 100,0 |

| Weight in kg: | 6 |

| Delivery condition: | Supplied fully assembled |

| Shipping information: | Depending on the order volume, delivery will be by parcel post or bulky goods. Partial deliveries are possible for dismountable products (e.g. stand mailboxes can be shipped separately). |

Frequently asked questions about letterbox systems

If your letterbox is in its original packaging, your keys are in the letterbox (take them out through the insertion slot) or in the enclosed bag (this also contains the assembly aid and other small parts). Every letterbox that leaves our premises is carefully checked and packed. A declaration of care is enclosed by the employee who manufactured your new product. If you still cannot find your key, please feel free to contact us.

DIN EN 13724

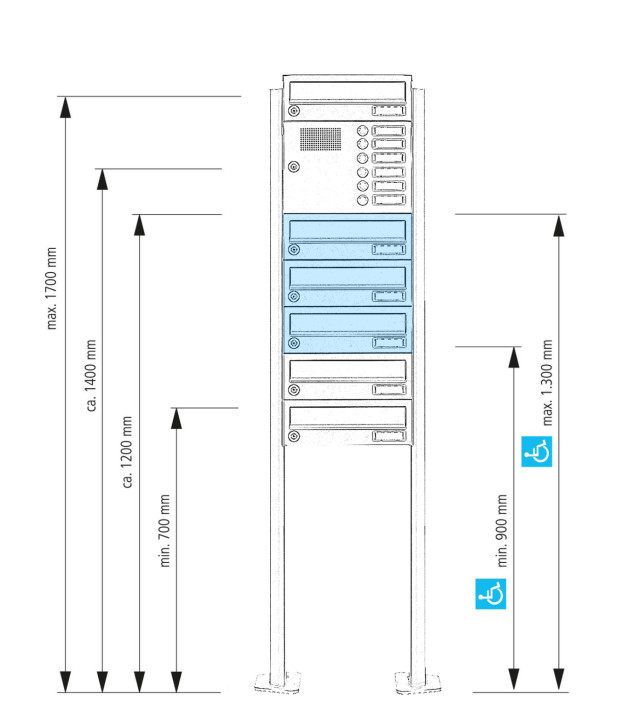

When planning a letterbox system, you should always observe the currently valid DIN EN 13724 (also known as the ‘letterbox standard’) so that you or your tenant do not have any problems receiving post.

DIN EN 13724 guarantees you:

• Easy mail delivery without bent letters or personal collection at a post office, e. B. for large DIN C4 envelopes

• Sufficient storage space for higher mail volumes

• No hassle with wet mail

• Best quality through specified and tested materials

• Security against rent reductions through standardised letterboxes

Our products are usually all tested according to this standard and marked accordingly. Only a few do not meet this standard. Find out more

Information about DIN formats that fit into the corresponding letterbox slot is cropping up more and more often. Here is a brief overview of the dimensions of the most common formats:

DIN A5: 148 x 210 mm

DIN A4: 210 x 297 mm

DIN A3: 297 x 420 mm

DIN B5: 176 x 250 mm

DIN B4: 250 x 353 mm

DIN B3: 353 x 500 mm

DIN C5: 162 x 229 mm

DIN C4: 229 x 324 mm

DIN C3: 324 x 458 mm

1.4301 is characterised by its good weldability with electrical processes. Even without heat treatment, the steel is corrosion resistant due to its low carbon content. The carbon content must be below a percentage of 0.08, although values below 0.05% are now common in practice. It can also be polished very well and is flexibly formable. It is approved for temperature stresses of up to 600 °C. Its high-quality appearance is particularly appreciated when polished.

X5CrNi18-10 is a relatively soft, nickel-containing, non-ferromagnetic austenitic steel. To keep the material rust-free and scale-resistant, 1.4301 contains a minimum of 13% chromium.

We now use 1.4301 stainless steel for the majority of our products. Compared to galvanised steel, this has the advantage of increased durability and sustainability. Our claim for a manufactured product is that it lasts a lifetime.

The material 1.4016 is part of the stainless steel group and is also known under the designation AISI 430 or X6Cr17.

This is referred to as ferritic steel and has a maximum chromium content of 18% (minimum 16%). Ferritic steel is highly magnetic, unlike austenitic steel grades. The special property of stainless ferritic chromium steel lies in its ferritic microstructure. This is what makes 1.4016 resistant to stress corrosion, which is usually the critical point in austenitic stainless steels. The drawback is the poor weldability of the material.

The material is characterised by its good bending, deep-drawing and polishing properties. Its insensitivity to stress corrosion cracking and its basic resistance to alkaline solutions, moisture or diluted organic acids, for example, should also be emphasised. It is not resistant to corrosion in salt water.

We now use 1.4016 stainless steel for the majority of our powder-coated products that do not require welding. Compared to galvanised steel, this has the advantage of increased durability and sustainability. Our claim for a manufactured product is that it will last a lifetime.

Powder coating is a tried and tested method of refining our surfaces. In this process, electrostatically charged powder coatings are applied to the respective workpieces using a spray gun. The parts then pass through a conveyor system to be baked in the oven. At temperatures of around 180° Celsius, the structures of the powder and the coated surface bond with each other. The heating process gives the powder a high-quality, smooth or evenly structured surface. We powder-coat metal parts such as steel, stainless steel, aluminium or other electrically conductive materials.

The advantages of powder coating include high corrosion protection and strong resilience. Coated parts are impact and scratch resistant, as well as resistant to chemicals and weathering.

Powder coating is a particularly environmentally friendly surface treatment technique, because no solvents or thinners are used in powder coatings. In addition, the powder coating process saves resources because the excess paint that is applied can be reclaimed.

We use both terms interchangeably, so the abrasive rating of our products always corresponds to 240 grit. This number indicates the roughness/grain size of the abrasive. The surface is matt.

The mailbox manufactory - tradition since 2003

At Briefkasten Manufaktur, you can order your letterbox, free-standing letterbox or letterbox system with countless customisations directly in the shop! Briefkasten Manufaktur only uses systems, components and individual parts from well-known manufacturers in Germany. But our customer service doesn't end with your order: After your order, you may receive a design drawing by email as a PDF to realise your wishes down to the last detail. Your wishes will be considered in detail and even special requests that go beyond our configuration offer can be realised. After your production approval, your letterbox is customised and conveniently delivered by parcel post. Our customer service does not end here either, we ensure that the stainless steel letterboxes, letterbox systems, doorbells and lights are delivered to you in perfect condition with customised packaging.

And if you don't like a product you have purchased or something is not to your liking, as a consumer you run no risk with us. You can return our products within two weeks.

Letterboxes in over 80 colours

At Briefkasten Manufaktur, you can choose from over 80 colours or your desired RAL colour code. In addition to a wide range of colours, we also offer premium finishes for an even more attractive look.

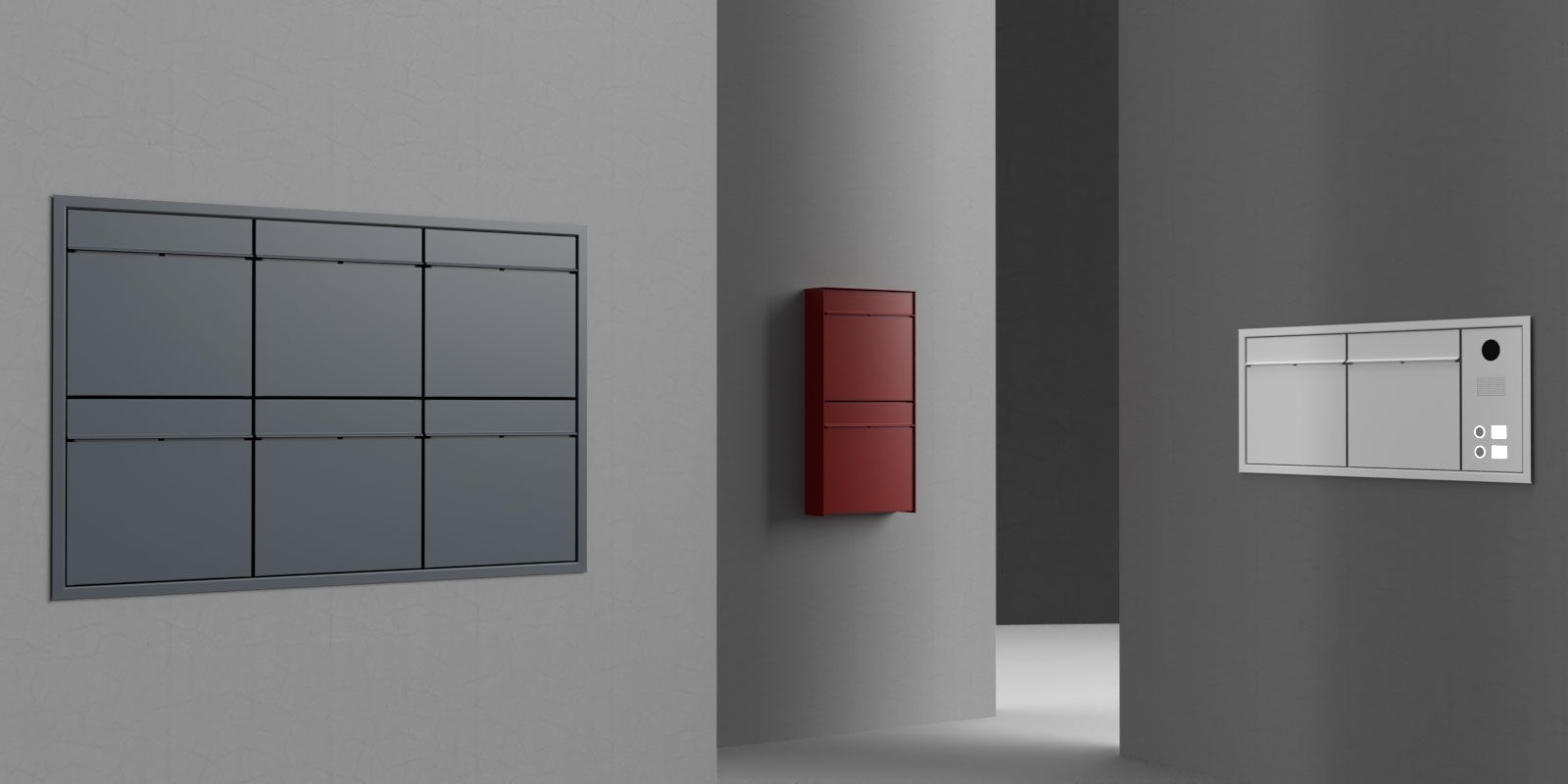

Design letterboxes. Variability through customisation.

Every product at Briefkasten Manufaktur is customised and is only made by hand for you after you place your order. Many of our products can therefore be ordered directly in the shop with countless customisations. This is possible thanks to the modular structure, flexible prefabrication, warehousing and logistics. Individual components are already prefabricated so that very short delivery times can be achieved in some cases.

Simple installation thanks to well thought-out designs

Our letterbox systems are supplied with detailed and easy-to-understand documentation and assembly aids and are usually fully assembled within a very short time.